In the fast-paced manufacturing world, having the right equipment is crucial for maximizing productivity, ensuring precision, and maintaining cost efficiency. Investing in high-quality industrial machines can streamline operations and boost overall output. If you’re setting up or upgrading your manufacturing facility, here are the top 5 industrial machines that every business should consider.

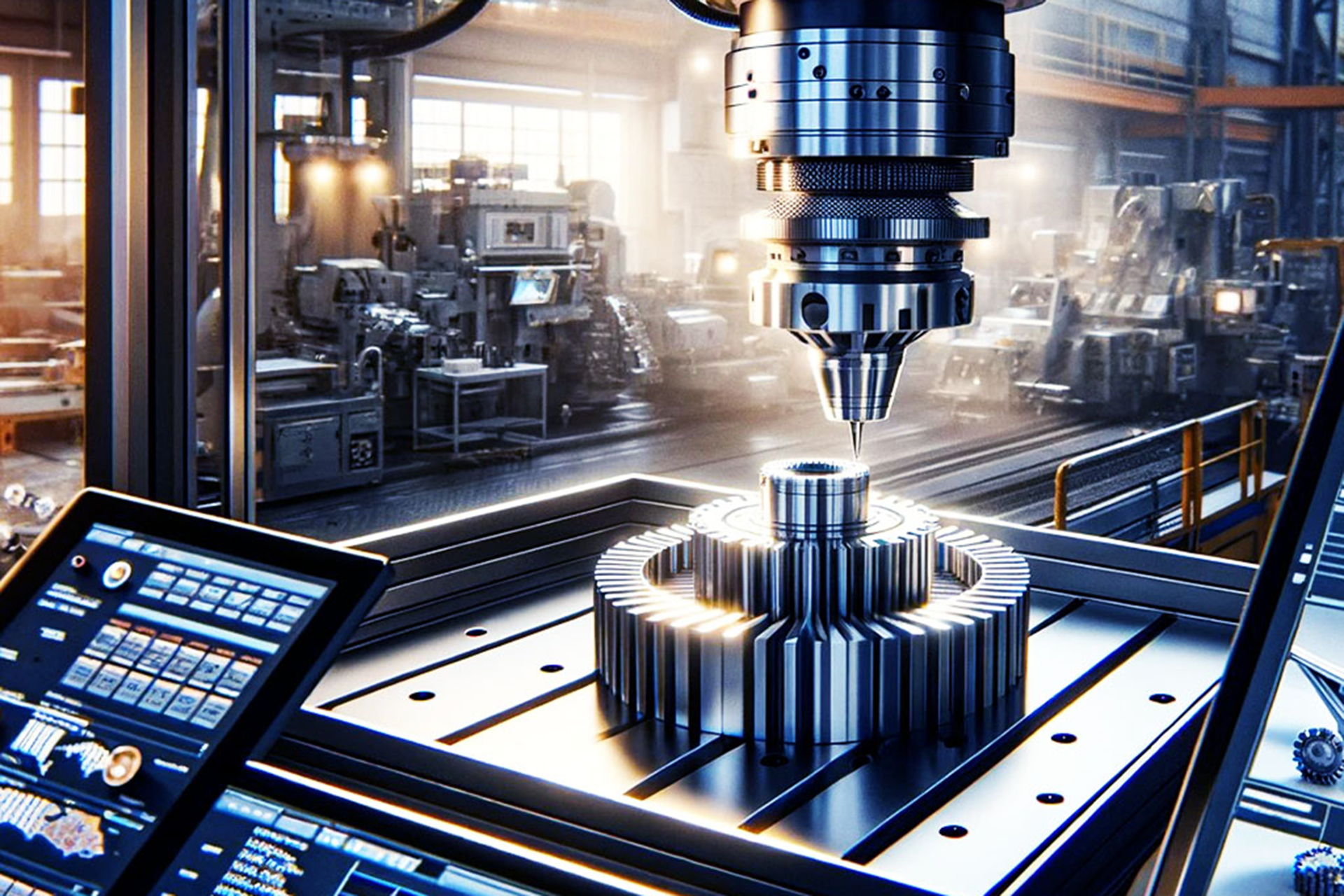

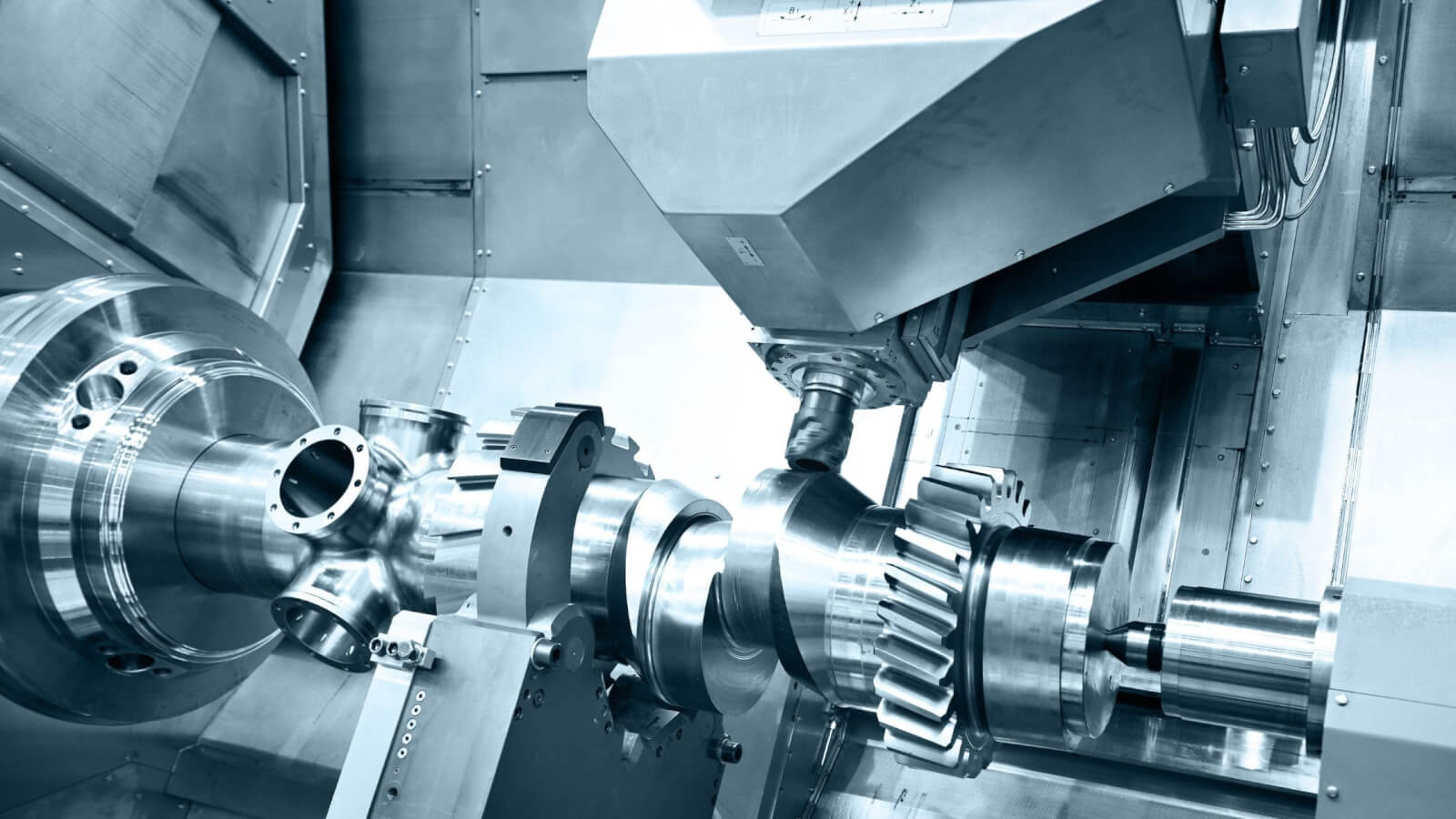

1. CNC Machines – Precision and Automation

CNC (Computer Numerical Control) machines are a must-have for any manufacturing business that requires high-precision cutting, milling, drilling, or engraving. These machines offer:

- Automation – decreasing manual work while boosting productivity.

- Consistency – Delivering precise results with minimal errors.

- Versatility – Handling various materials, including metal, wood, and plastic.

2. Industrial 3D Printers – Rapid Prototyping and Customization

Modern manufacturing relies heavily on rapid prototyping, and industrial 3D printers make it possible to create models and parts quickly. Key benefits include:

- Faster Product Development – Speeding up design iterations and testing.

- Cost Efficiency – Reducing waste compared to traditional manufacturing methods.

- Customization – Allowing for highly detailed and unique product designs.

3. Automated Conveyor Systems – Efficient Material Handling

For businesses focused on mass production, an automated conveyor system is essential. These systems:

- Improve Workflow – Reducing manual transport of materials and products.

- Enhance Safety – Minimizing workplace injuries caused by heavy lifting.

- Increase Productivity – ensuring smooth and fast material movement across production lines.

4. Laser Cutting Machines – High-Speed Precision Cutting

Laser cutting machines provide clean, accurate, and high-speed cutting for materials like metal, plastic, and glass. Why invest in one?

- Superior Edge Quality – No need for additional finishing work.

- Reduced Waste – Maximizing material usage with minimal errors.

- Flexibility – Ideal for a variety of industries, from automotive to electronics.

5. Industrial Robotics – Automation for Maximum Efficiency

As manufacturing evolves, industrial robots are becoming indispensable for automating tasks such as welding, assembly, and packaging. These machines offer:

- 24/7 Operation – Improving production rates and reducing downtime.

- High Precision – Delivering consistent results for complex tasks.

- Labor Cost Savings – Minimizing reliance on manual labor for repetitive work.

Final Thoughts

Investing in the right industrial machines can significantly impact your manufacturing business’s efficiency, quality, and profitability. Whether it’s CNC machining for precision, 3D printing for innovation, or automation for productivity, these machines help streamline operations and help companies stay ahead of the competition.

Looking to upgrade your manufacturing setup? Choose machines that align with your business goals and future growth!