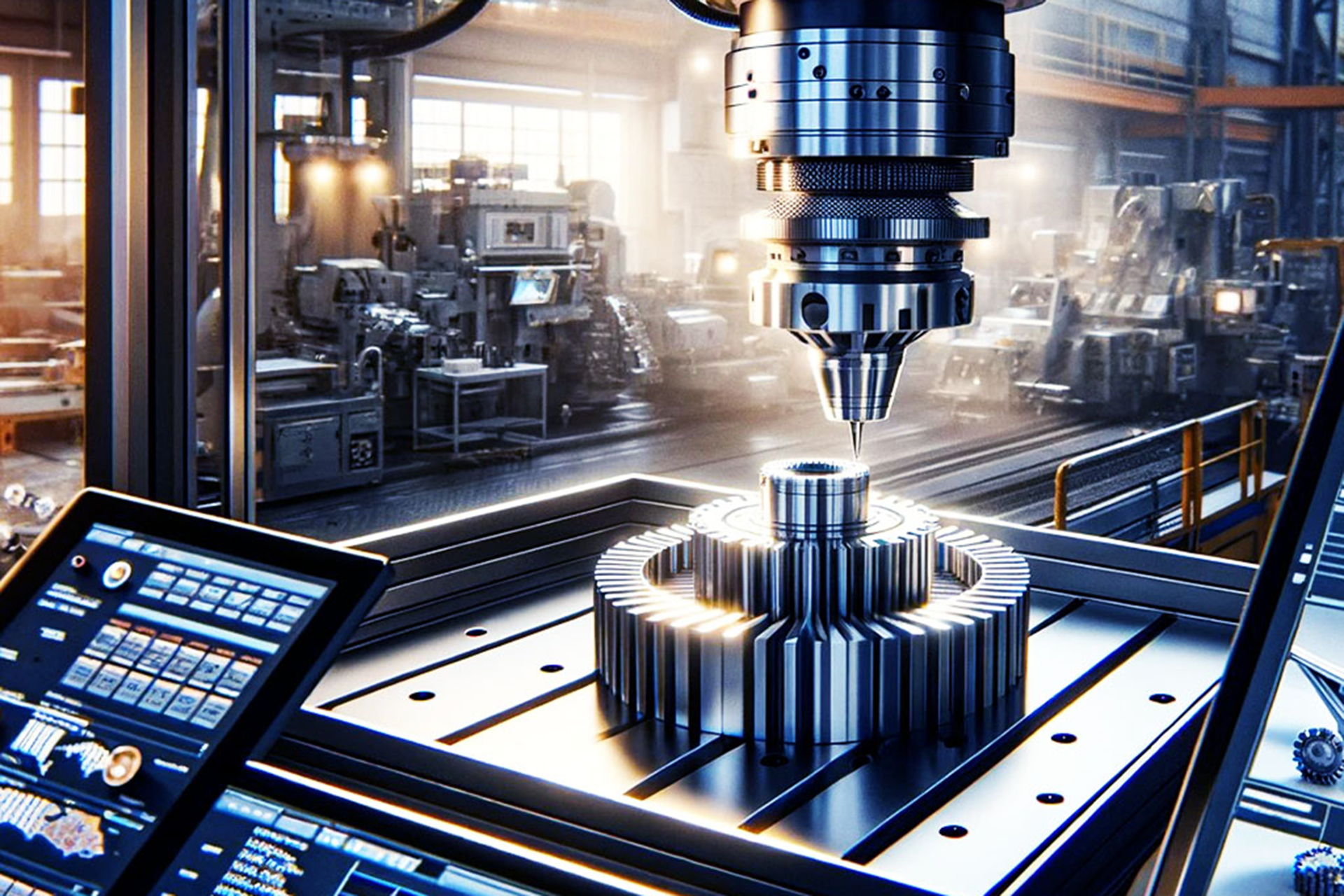

Selecting the right CNC machine is crucial for any manufacturing business, especially considering the future of CNC machining and evolving industry demands.. This decision directly impacts your production efficiency, product quality, and operational costs. Different industries have unique requirements, and choosing a CNC machine accordingly can be a great investment. This guide will help you understand how to select the best CNC machine for your industry.

Understanding Different Types of CNC Machines

Before choosing a machine for your industry, it’s essential to understand different types of CNC machines:

- CNC Milling Machine – Used for cutting and shaping metal, wood, and plastic.

- CNC Lathe Machine – Best for manufacturing cylindrical components with high precision.

- CNC Laser Cutting Machine – Ideal for intricate cutting on various materials.

- CNC Plasma Cutter – Designed for heavy-duty metal sheet cutting.

- CNC Grinding Machine – Used to achieve smooth and polished surfaces.

How to Choose the Best CNC Machine for Your Industry?

1. Aerospace Industry: High Precision and Complex Designs

Aerospace parts require extreme accuracy and reliability. For this industry, the following features are essential:

- 5-Axis CNC Machines – Used for manufacturing complex and intricate aerospace parts.

- Titanium & Aluminum Compatibility – Machines should handle high-strength metals efficiently.

- Automated Quality Control – Ensures compliance with strict industry standards.

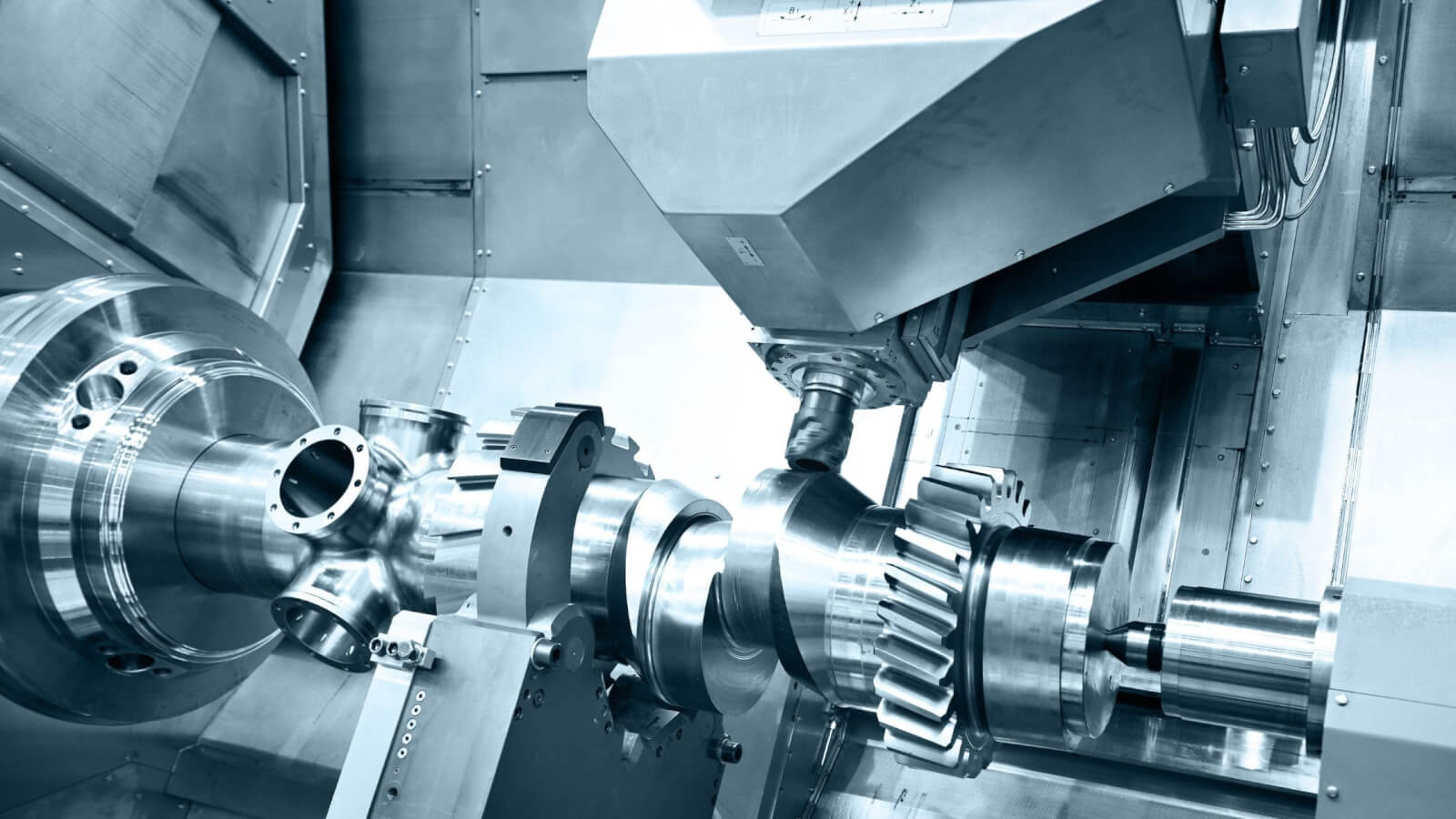

2. Automotive Industry: Speed and Mass Production

The automotive industry requires CNC machines that can handle large-scale production. Key features include:

- High-Speed CNC Lathes & Milling Machines – For engine and chassis components.

- Automation & Robotics Integration – Reduces manual intervention and increases efficiency.

- Multi-Axis Capabilities – Ideal for producing complex, multi-dimensional parts.

3. General Manufacturing: Versatility and Cost-Effectiveness

If your business produces multiple products, you need a versatile CNC machine. Consider the following factors:

- Multi-Purpose CNC Machines – Should handle various materials and operations.

- User-Friendly Software – Makes programming and setup easier.

- Affordable Maintenance & Durability – Reduces downtime and extends lifespan.

4. Medical Equipment Manufacturing: Extreme Accuracy and Clean Operation

The medical industry demands high-precision and sterile production environments. Key features include:

- Micromachining Capabilities – Required for manufacturing surgical and medical instruments.

- Non-Contaminating Lubrication Systems – Ensures a clean and hygienic production process.

- High-Speed Spindles – Provides fine precision for stainless steel and titanium parts.

5. Woodworking & Furniture Industry: Precision Cutting and Engraving

If your business is involved in furniture production or woodworking, consider these features:

- Router CNC Machines – Ideal for cutting, carving, and engraving.

- Large Worktable Capacity – Handles large wood sheets and panels efficiently.

- Dust Collection Systems – Ensures clean and smooth operation.

Key Factors to Consider Before Buying a CNC Machine

Regardless of the industry, consider the following factors before purchasing a CNC machine:

- Material Compatibility – Ensure the machine can process the materials you need.

- Software & Programming – Look for user-friendly and advanced software.

- Production Volume – Choose a machine that can efficiently handle your workload.

- Budget & ROI – Avoid cheap machines; a good investment always pays off.

- After-Sales Support & Warranty – Always buy from certified and authorized dealers.

Choosing the right CNC machine is crucial for your business’s success and efficiency. Every industry has unique requirements, and selecting the right machine based on these needs can take your business to the next level. Whether you are in aerospace, automotive, medical, woodworking, or general manufacturing, there is a perfect CNC machine available—you just need to make the best choice for your needs!