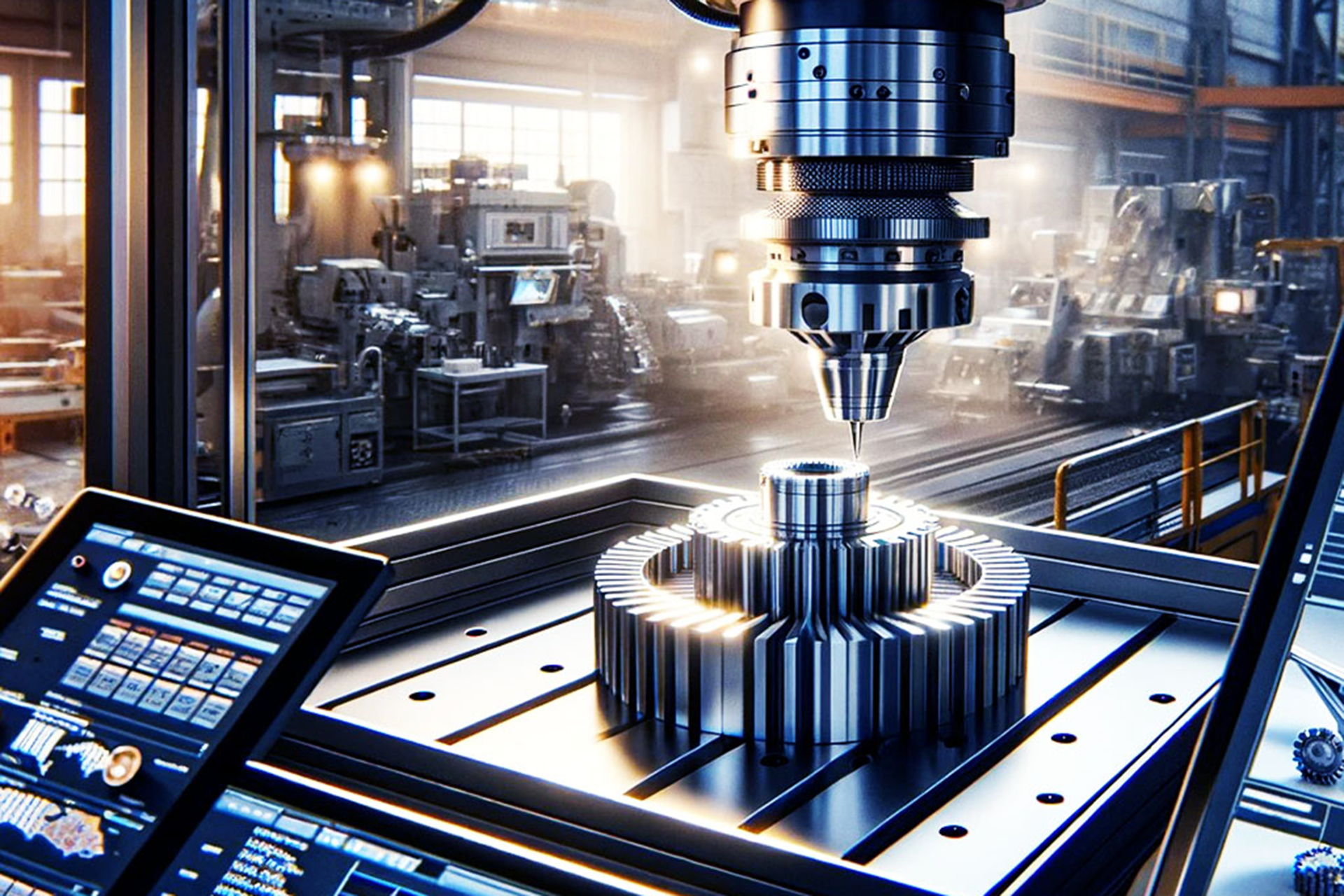

CNC machining has been a cornerstone of precision manufacturing for decades, and as we step into 2025, the industry is undergoing groundbreaking advancements. From AI-driven automation to sustainable machining practices, the future of CNC machining is more promising than ever. In this blog, we explore the top trends and innovations shaping the industry and how CTME is leading the way as a thought leader in CNC technology.

1. AI & Machine Learning Integration

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing CNC machining by enhancing efficiency, accuracy, and predictive maintenance. Smart CNC machines can now:

- Self-optimizing cutting paths for reduced waste.

- Detect potential failures before they happen, minimizing downtime.

- Adapt in real time to changing production needs.

CTME is at the forefront of AI-powered CNC solutions, ensuring that businesses achieve maximum precision with minimal errors.

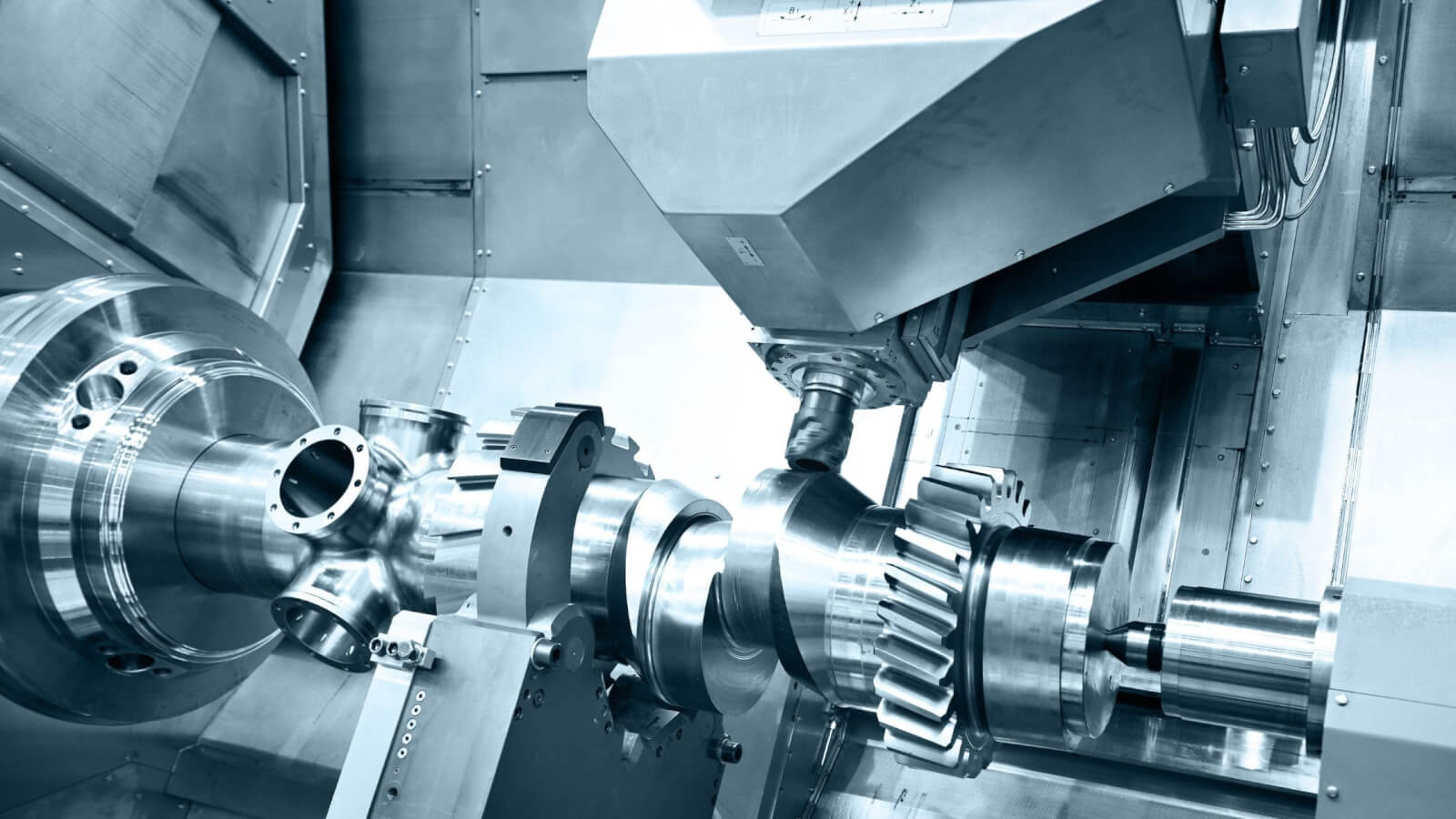

2. Automation & Lights-Out Manufacturing

With advancements in robotics and IoT, CNC machining is moving towards fully automated, lights-out manufacturing. This means:

- 24/7 production with minimal human intervention.

- Faster turnaround times and improved productivity.

- Enhanced safety by reducing manual labor in high-risk environments.

At CTME, we specialize in integrating smart automation into CNC workflows, helping businesses scale without increasing labor costs.

3. Sustainable & Eco-Friendly Machining

As industries focus on green manufacturing, CNC machining is adopting more sustainable practices, such as:

- Coolant recycling systems to reduce water waste.

- Energy-efficient CNC machines that consume less power.

- Minimized material waste through optimized cutting techniques.

CTME is committed to promoting environmentally responsible machining, ensuring that efficiency does not come at the cost of sustainability.

4. Hybrid Manufacturing: CNC + 3D Printing

The integration of additive manufacturing (3D printing) with CNC machining is a game-changer, allowing manufacturers to:

Client Testimonial

The integration of additive manufacturing (3D printing) with CNC machining is a game-changer, allowing manufacturers to:

- Creating complex geometries that were previously impossible.

- Reduce material waste with precise layering.

- Speed up prototyping and production cycles.

CTME is pioneering hybrid manufacturing solutions, giving businesses the best of both worlds additive flexibility with CNC precision.

5. Advanced CNC Software & Cloud Connectivity

The rise of cloud-based CNC software and IoT-enabled machines means:

- Real-time monitoring of production from anywhere in the world.

- Remote troubleshooting & updates to improve uptime.

- Seamless data integration for smarter decision-making.

CTME is dedicated to providing cutting-edge CNC software solutions, empowering businesses with full control and visibility over their operations.

The future of CNC machining is driven by AI, automation, sustainability, and hybrid manufacturing. As these trends continue to evolve, companies must adapt to stay competitive. CTME is leading the way by delivering state-of-the-art CNC solutions, ensuring businesses stay ahead of industry advancements.

Are you ready to embrace the future of CNC machining? Partner with CTME and take your manufacturing to the next level!