Efficiency is essential to retaining competitive in the fast-paced production world of today. Robotics and automation have revolutionized industrial processes by enhancing precision, reducing downtime, and increasing productivity. Integrating these technologies into your manufacturing setup can help streamline operations, cut costs, and improve product quality.

The Role of Robotics & Automation in Manufacturing

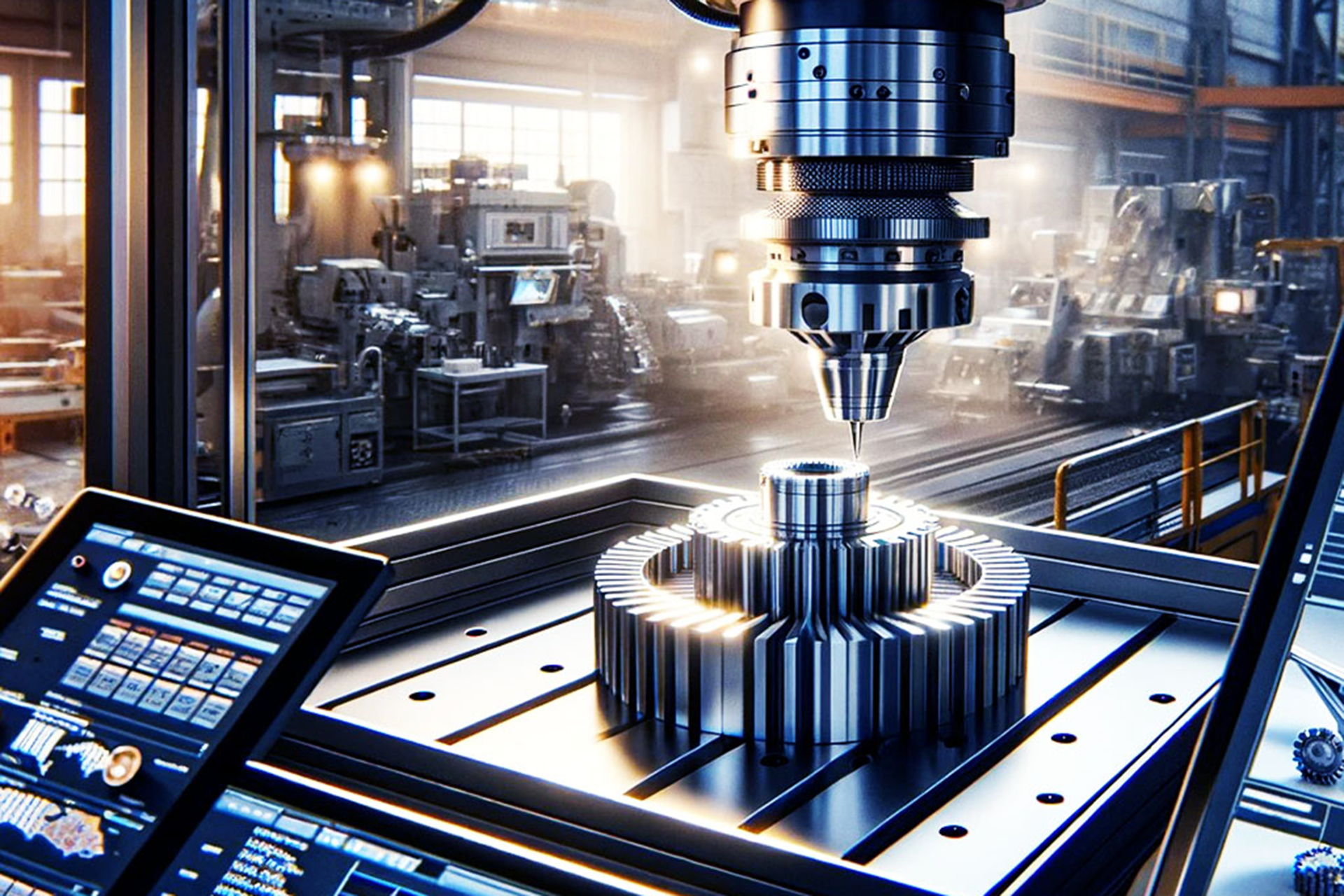

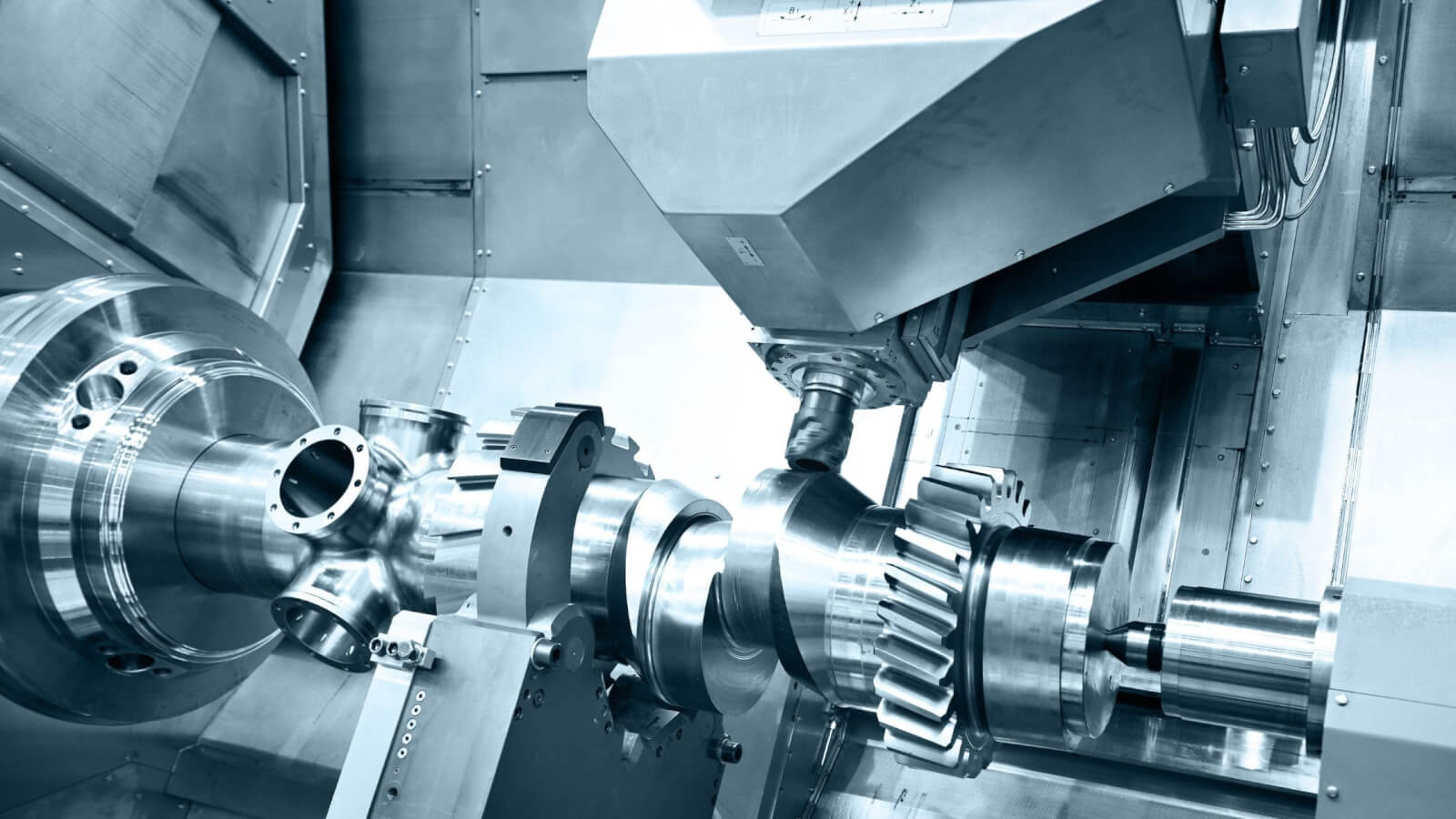

Robotic systems and automated machinery are designed to handle repetitive tasks with high accuracy, allowing manufacturers to optimize production lines. By reducing human intervention, these technologies minimize errors, improve safety, and ensure consistent output.

Key Benefits of Robotics & Automation

1. Increased Productivity

Automated systems operate 24/7, significantly boosting production capacity. Unlike human workers, robots don’t require breaks, resulting in higher output and faster turnaround times.

2. Enhanced Precision & Consistency

Robotic systems eliminate human errors and ensure consistent quality in every product. This is particularly beneficial for industries requiring high precision, such as aerospace and medical device manufacturing.

3. Cost Reduction

Although automation requires an initial investment, it drastically reduces long-term operational costs. Robots lower labor expenses, minimize material waste, and reduce machine downtime through predictive maintenance.

4. Improved Workplace Safety

Repetitive tasks and hazardous environments pose risks to human workers. Robotics can handle dangerous operations, such as heavy lifting and exposure to toxic substances, reducing workplace injuries and ensuring a safer working environment.

5. Scalability & Flexibility

Modern robotic systems can be reprogrammed and adapted to different tasks, making them a flexible solution for various manufacturing needs. Whether you need to scale production up or introduce new product lines, automation makes transitions seamless.

Industries Benefiting from Robotics & Automation

Automotive: Robots handle welding, painting, and assembly, increasing production speed and precision.

Electronics: Automated machines assemble intricate components with high accuracy.

Pharmaceuticals: Robotics ensure precise formulation, packaging, and quality control.

Food & Beverage: Automated systems streamline packaging, sorting, and quality inspection processes.

How to Implement Robotics & Automation in Your Manufacturing Process

- Assess Your Needs – Identify areas in your production line that can benefit from automation.

- Choose the Right Technology – Invest in robots and automation solutions that align with your industry and workflow.

- Train Your Workforce – Equip employees with the skills to operate and maintain automated systems.

- Integrate Smart Monitoring – Use IoT-enabled automation for real-time performance tracking and predictive maintenance.

- Optimize & Scale Gradually – Start with partial automation and expand as needed to maximize efficiency.

Robotics and automation are revolutionizing the manufacturing industry by enhancing efficiency, reducing errors, and cutting production costs. By integrating advanced CNC machines with robotic automation, businesses can achieve higher precision, faster production cycles, and improved workplace safety. As technology continues to evolve, investing in automation is no longer a luxury but a necessity for staying competitive in the modern manufacturing landscape.