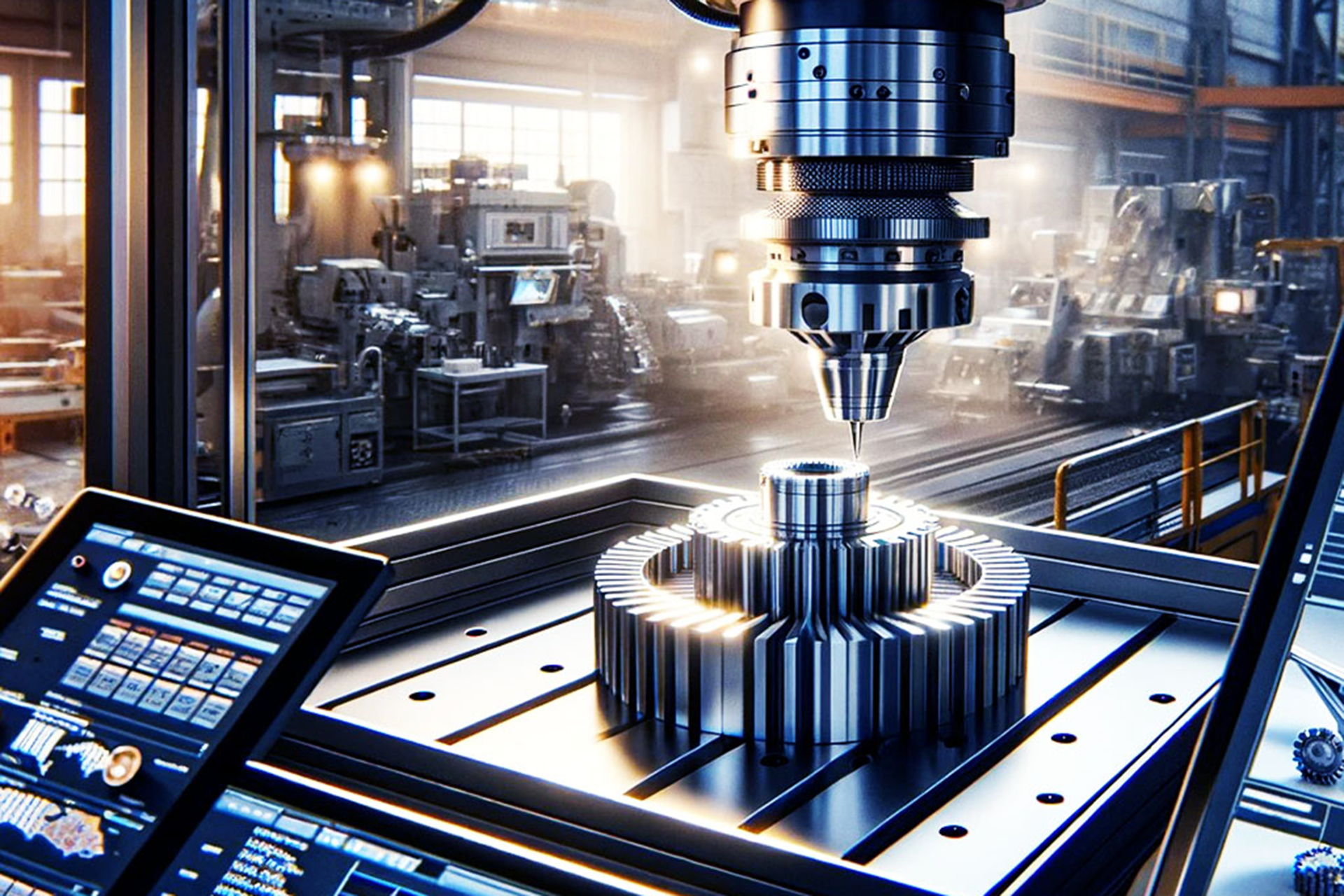

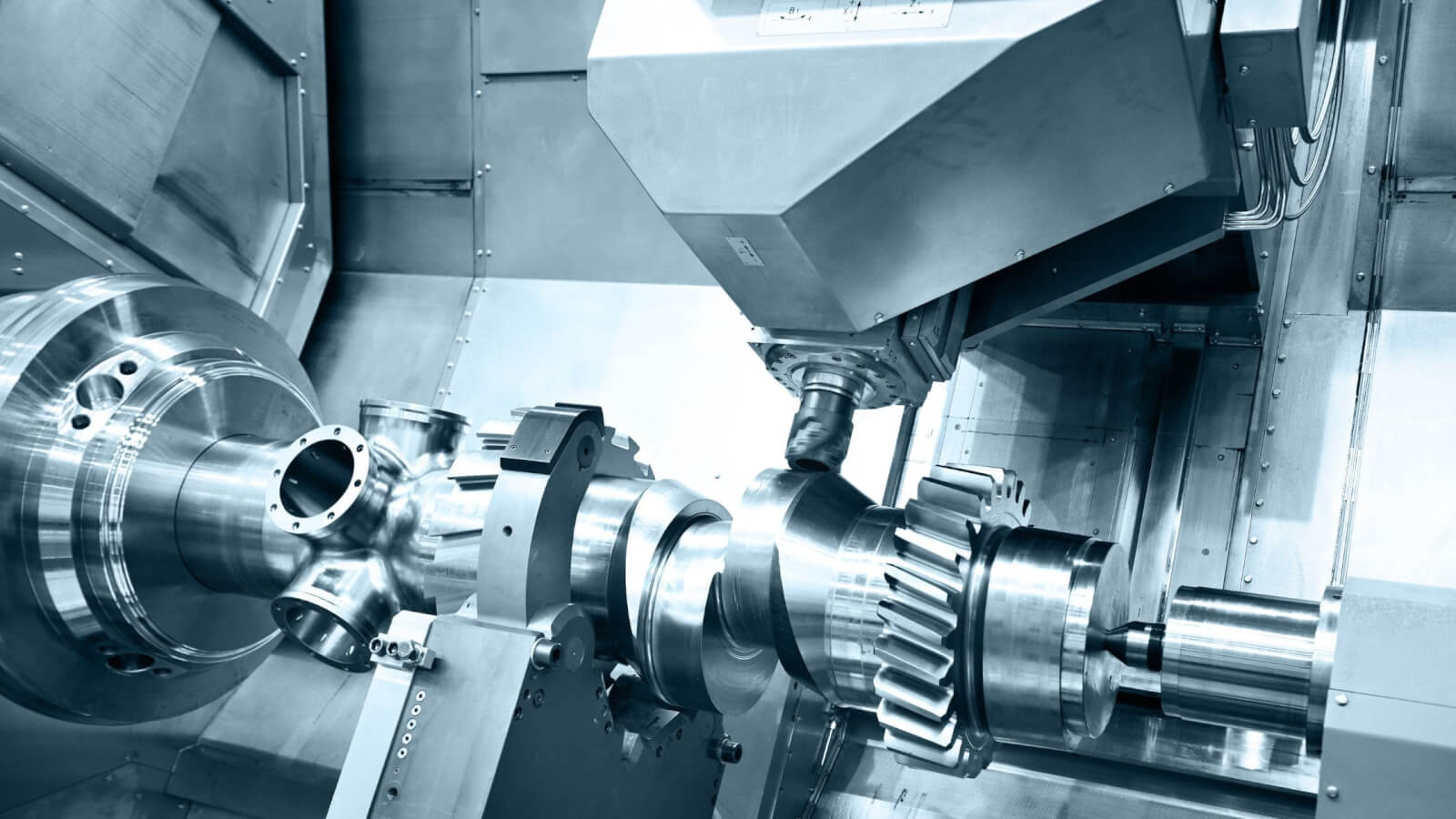

CNC machines are the backbone of modern manufacturing, offering precision, efficiency, and automation. However, like any complex machinery, they can encounter operational issues that may lead to downtime and reduced productivity. Understanding these problems and their solutions can help businesses keep their machines running smoothly. In this guide, we’ll explore some common CNC machine problems and how to fix them.

1. The CNC Machine is Not Powering On

Possible Causes:

- Loose or faulty power connections.

- Blown fuses or tripped circuit breakers.

- Malfunctioning power supply unit.

✅ Check the power supply and ensure all connections are secure.

✅ Inspect fuses and circuit breakers, replacing any that are blown.

✅ Test the power supply unit and replace it if necessary.

2. Inaccurate Cutting or Positioning Errors

Loose or misaligned machine components.

Worn-out ball screws or guide rails.

Incorrect tool calibration.

Possible Causes:

- Loose or misaligned machine components.

- Worn-out ball screws or guide rails.

- Incorrect tool calibration.

How to Fix:

✅ Tighten all bolts and check for misalignment.

✅ Inspect and replace worn-out ball screws or rails.

✅ Recalibrate the machine tools according to manufacturer guidelines.

3. Excessive Vibration During Operation

Possible Causes:

- Loose or unbalanced machine components.

- Improper tool selection or settings.

- Faulty spindle bearings.

How to Fix:

✅ Ensure all components are properly secured and balanced.

✅ Choose the correct cutting tools and settings for the material.

✅ Check spindle bearings for wear and replace them if needed.

4. Tool Breakage or Premature Wear

Possible Causes:

- Incorrect cutting speeds and feeds.

- Poor-quality or dull cutting tools.

- Excessive tool load.

How to Fix:

✅ Optimize cutting speeds and feeds based on material type.

✅ Use high-quality, sharp cutting tools and replace them regularly.

✅ Reduce tool load by adjusting depth and feed rate.

5. Overheating and Coolant Issues

Possible Causes:

- Insufficient coolant flow.

- Clogged coolant nozzles.

- Coolant contamination.

How to Fix:

✅ Check coolant levels and refill if necessary.

✅ Clean or replace clogged coolant nozzles.

✅ Regularly maintain and filter the coolant system to prevent contamination.

6. Machine Stalling or Unexpected Shutdowns

Possible Causes:

- Overloaded motor or drive system.

- Software glitches or incorrect G-code.

- Electrical component failure.

How to Fix:

✅ Reduce load by adjusting feed rates and cutting depth.

✅ Check the control software for errors and reload the G-code.

✅ Inspect electrical components and replace faulty parts.

Regular maintenance and troubleshooting can prevent costly downtime and keep CNC machines operating at peak performance. By addressing these common issues promptly, manufacturers can increase productivity, extend machine lifespan, and reduce repair costs.

Need expert help with CNC troubleshooting? CTME provides industry-leading support and maintenance solutions to keep your machines running efficiently!