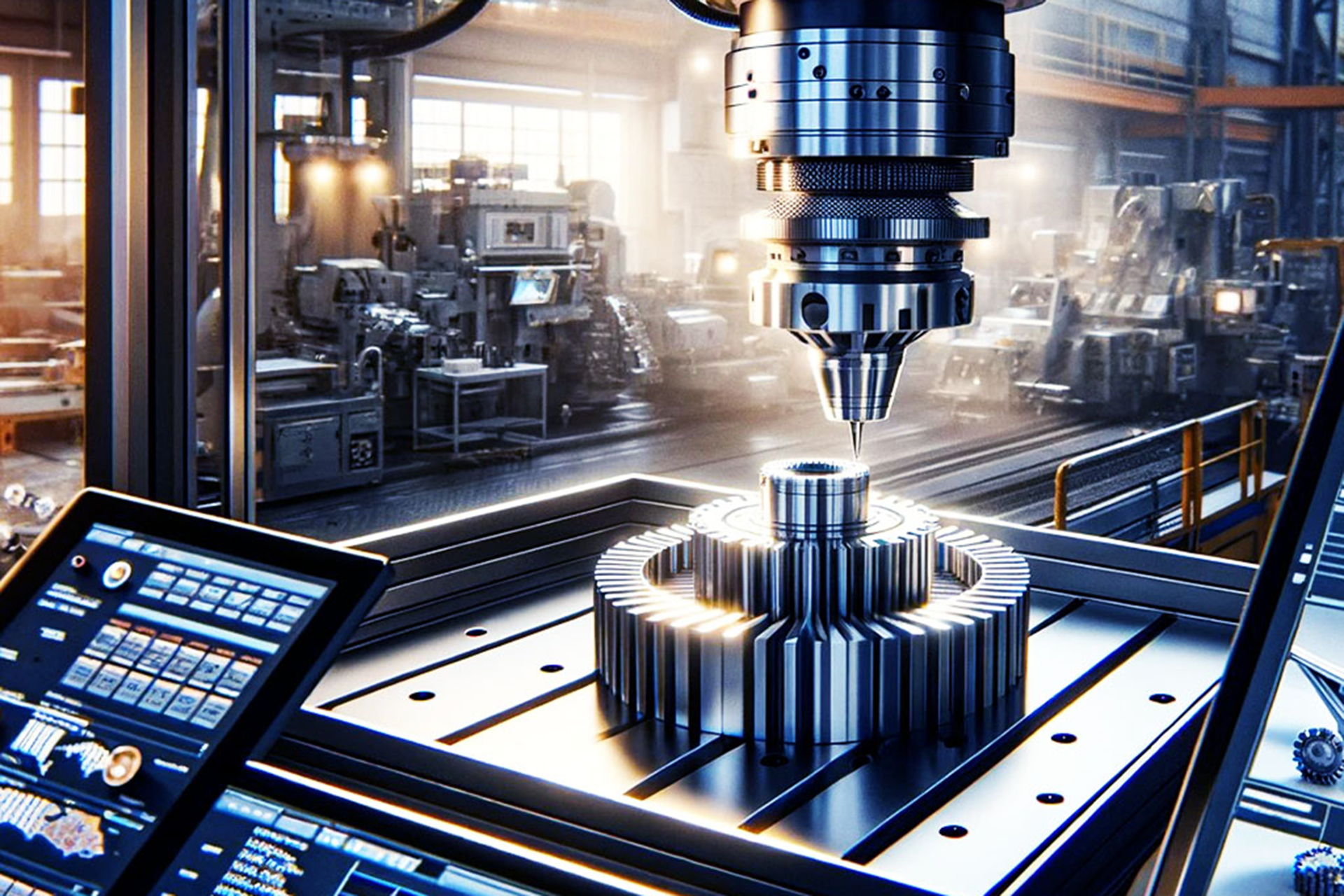

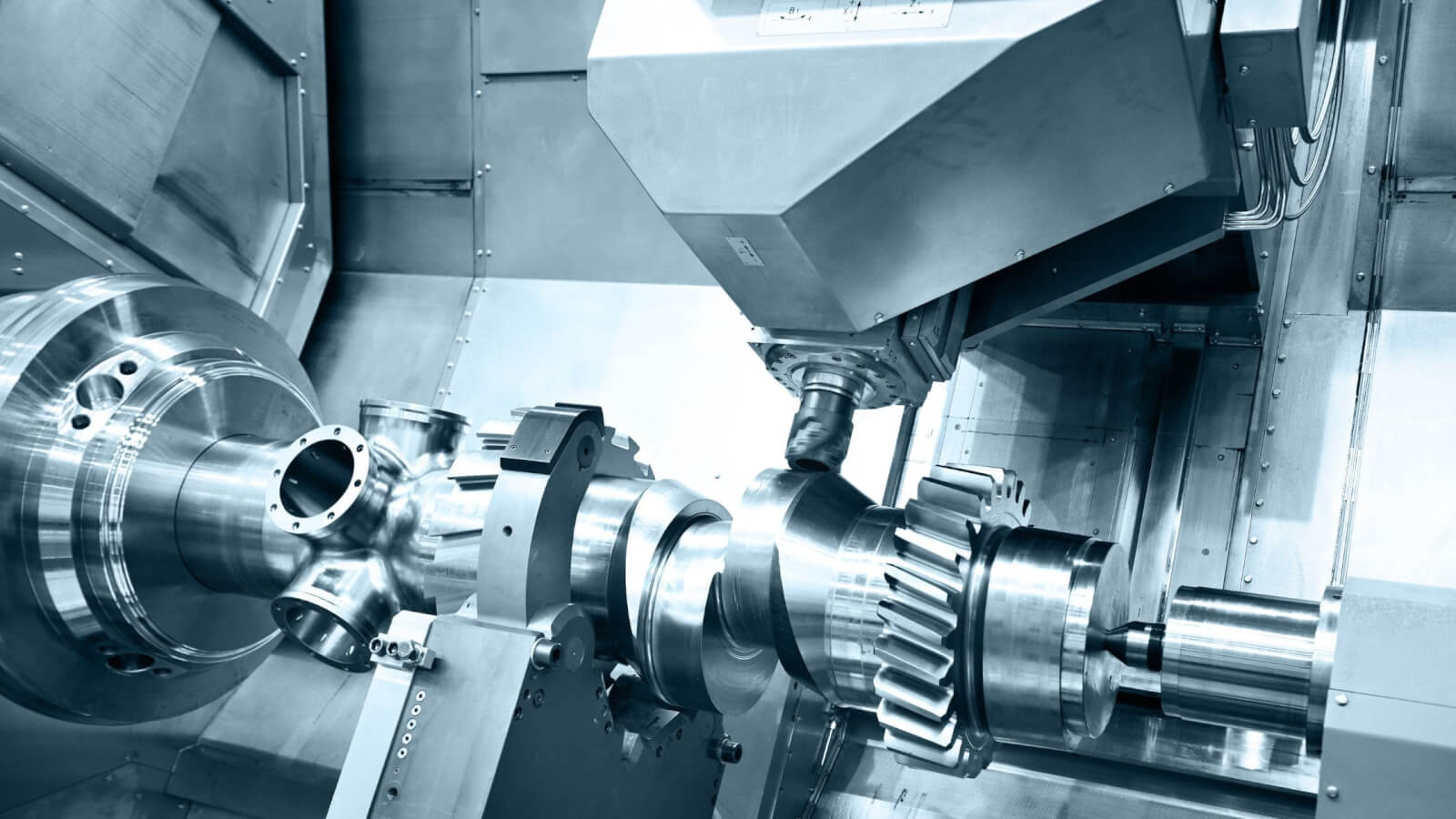

CNC and industrial machines are valuable assets that drive efficiency, precision, and productivity in manufacturing. However, without proper maintenance, these machines can experience breakdowns, reduced accuracy, and costly downtime. To ensure maximum performance and extended lifespan, businesses must adopt a preventive maintenance routine. Here are essential tips to keep your CNC and industrial machines running at their best.

1. Regular Cleaning & Lubrication

Why It’s Important:

Dust, debris, and residue buildup can affect machine accuracy and wear out moving parts By lowering friction, proper lubrication helps to avoid premature wear and tear.

Maintenance Tips:

Clean work surfaces, cutting tools, and machine components after each operation.

Remove metal shavings and coolant residues from the machine beds.

Apply manufacturer-recommended lubricants to guide rails, ball screws, and bearings.

2. Monitor and Replace Worn Parts

Why It’s Important:

Worn-out components can lead to decreased performance and unexpected failures, resulting in costly repairs and downtime.

Maintenance Tips:

Regularly inspect belts, bearings, seals, and hoses for signs of wear.

Replace damaged or worn parts before they fail to avoid costly breakdowns.

Maintain a supply of necessary spare parts on hand for prompt replacements.

4. Keep Machine Software and Firmware Updated

Why It’s Important:

Updated software ensures optimal machine performance, security, and compatibility with new technologies.

Maintenance Tips:

Regularly check for manufacturer software updates and install them as recommended.

Back up your CNC machine programs and settings to prevent data loss.

Calibrate the control system periodically to maintain precision.

4. Check and Maintain Coolant Systems

Why It’s Important:

Coolant plays a vital role in preventing overheating and reducing tool wear. Contaminated or low coolant levels can lead to machine malfunctions.

Maintenance Tips:

Check the coolant levels frequently and add more as necessary.

Clean and replace coolant filters to prevent clogging.

Ensure the coolant mix is correct to maintain proper cooling and lubrication.

5. Align and Calibrate Machine Components

Why It’s Important:

Misalignment can cause inaccurate cuts, poor-quality finishes, and increased tool wear.

Maintenance Tips:

Regularly check machine alignment using precision measuring tools.

Perform test runs to ensure accuracy and recalibrate if needed.

Tighten loose fasteners and realign components as per manufacturer guidelines.

6. Train Operators on Proper Usage & Maintenance

Why It’s Important:

Untrained operators can mishandle machines, leading to increased wear, breakdowns, and inefficient performance.

Maintenance Tips:

Provide regular training sessions on machine operation and maintenance.

Encourage operators to report unusual noises, vibrations, or malfunctions immediately.

Implement a maintenance checklist to ensure consistent upkeep.

Final Thoughts

Preventive maintenance is the key to maximizing the performance, reliability, and lifespan of CNC and industrial machines. By following these essential maintenance tips, businesses can reduce downtime, prevent costly repairs, and ensure seamless production.

Need expert maintenance services? CTME provides comprehensive CNC and industrial machine maintenance solutions to keep your operations running smoothly!